We’ve partnered with Rosenbauer to offer an extinguishing system for high-voltage RFC (regenerative fuel cell) batteries. This allows the safe, efficient and fast extinguishing of batteries based on lithium-ion technology, and enables direct cooling of the battery modules (or the cells within the modules) and thus a quick stop of the propagation of the thermal runaway of the cells.

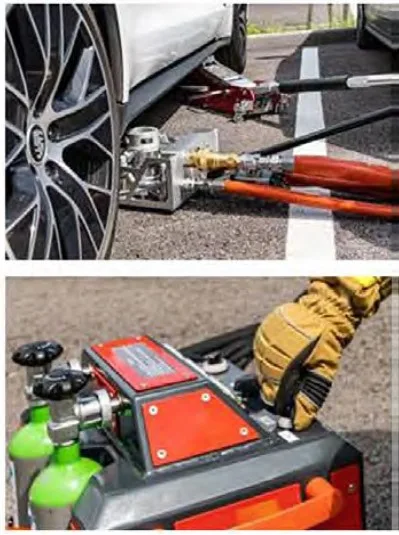

The system consists of two main components – the extinguishing unit and the operating unit, which are connected to one another with hoses. The extinguishing unit is positioned on the battery and – if necessary -jacked on the car body or other points. The preferred position of the extinguishing unit is on the underside of the vehicle.

The operating unit triggers the penetration of the piercing tool into the battery housing from a safe distance away. Immediately after piercing, the battery housing is flooded with water and the efficient cooling process starts.

Advantages

Safe

The firefighters only spend a short period of time in the direct vicinity of the electric vehicle to be extinguished. This short time near the vehicle reduces the risk of contamination with the smoke gas constituents if the battery is evaporating gas.

Efficient

The extinguishing system brings the extinguishing water exactly where it is needed – to cool the cells and modules in the battery housing. This means that extinguishing is very resource-saving and the spread of smoke gases is reduced to a minimum.

Fast penetration

Thanks to the special penetration method of the piercing tool, all currently known and tested battery housings can be safely penetrated.

Self-sufficient

The energy required for penetration is provided by compressed air cylinders.

Tested under real conditions

During the research and development, numerous fire tests were carried out with a large number of battery systems and complete vehicles. The system was tested on all common cell types (round, pouch or prismatic cells) in the platforms of European and American cars and trucks. The batteries tested had a capacity of up to 120 kWh.

Proven in practice

Factory, professional and voluntary fire brigades in Europe have been testing the extinguishing system for months and are providing important feedback from practice.

Normal pressure extinguishing system

The extinguishing system only needs water with a pressure of 4-10 bar as an extinguishing medium. This means that every existing normal pressure extinguishing system can be used.

Extinguishing water is fed in via a Storz C connection or other compatible hose couplings on the extinguishing hose line.