What are F gases?

F gases are a group of gases containing fluorine. HFCs are widely used in industrial applications because of their thermal and electrical properties. However, some HFCs have high GWP making them a significant contributor to climate change.

F gases include all HFC refrigerants, including R134a, R407C, R410A and R404A, used in refrigeration and HVAC systems. HFO refrigerants, which have lower GWPs, have emerged as a more environmentally-friendly alternative.

What are the key requirements for marine operators?

Ban on virgin very high GWP F gases

Virgin (unused) F gases cannot be used to refill existing refrigeration systems when the F gas has a global warming potential (GWP) above 2,500, unless the quantity of refrigerant in the system is equivalent to 40 tonnes or less of carbon dioxide (CO2). Examples are R-404A (3922 GWP), R-507A (3985 GWP), R-422D (2729 GWP).

Leak prevention and repair

Vessels must ensure regular checks are conducted on systems containing F gases to detect and prevent leaks. The frequency of these checks depends on the amount of refrigerant in the system and the GWP of the refrigerant used. Any detected leaks must be repaired without delay to prevent F-gas emissions. See Government guidance for further details.

Maintenance and record keeping

Operators must keep detailed records of their refrigeration and HVAC systems. This includes the quantity and type of F gases used, maintenance activities, and leak detection checks.

These records must be maintained and made available for inspection by authorities.

Reporting obligations

Engineers may be required to annually report on the quantity of F gases used, emitted, or recovered from their systems to relevant authorities.

F gas certification

Those working on refrigeration and HVAC systems containing F gases must be appropriately certified, to ensure they’re properly trained to minimise emissions and handle refrigerants safely.

Proper labelling

All equipment containing F gases must be labelled with information on the type and quantity of refrigerant. This labelling aids in the proper handling and disposal of equipment. For more information, see Government guidance.

End-of-life management

When decommissioning equipment, F gases must be properly recovered to prevent their release into the atmosphere. This might involve working with certified waste management services. It’s important not to mix different types of refrigerants, as most HFC refrigerants can be reclaimed and reused after proper processing by a certified waste handling facility. However, mixing them can make this process much more difficult – or even impossible.

Future-proof your onboard refrigeration & HVAC systems now

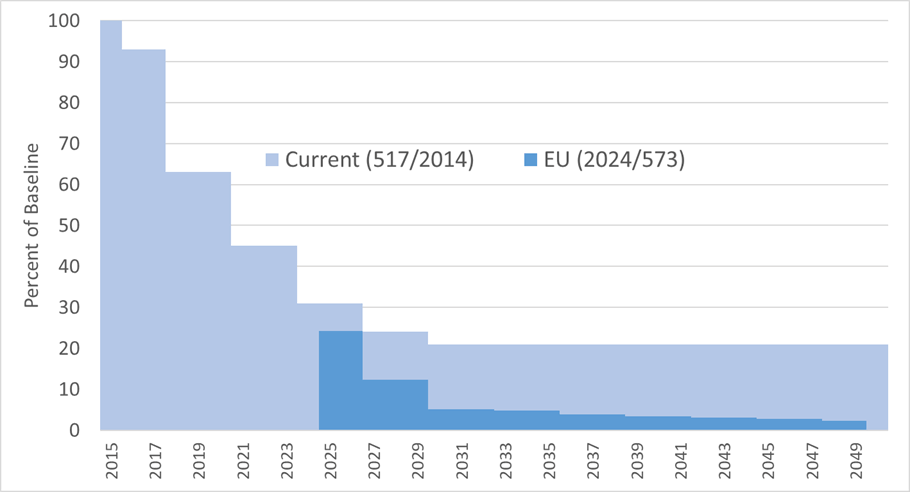

Those responsible for on-board refrigeration and HVAC systems need to transition to alternative gases with lower GWPs, if they haven’t already.

Aside from the legal obligation and environmental responsibilities, prices for legacy gases are on the rise, and availability is dropping significantly as the phase out progresses.

One option is to install entirely new systems, which will ensure F gas compliance from the outset, but has significant cost and downtime implications.

Another solution is to modify (retrofit) existing systems with new components and controls that allow for the use of alternative refrigerants. This can involve replacing compressors, condensers, and other critical components to ensure compatibility.

It’s a simple, convenient and low-cost way to extend the operational life of existing units, and allows the use of our RS Series of drop-in replacements, which are HFO refrigerants designed to replace R22 and R404A, R507 and all 400 series gases, as well as RS-53 (the only drop-in replacement for R410, with approximately half the GWP) ensuring you are F gas compliant until 2030.