Case study: HVAC system repair and maintenance aboard Hanson Thames

A routine HVAC check turned urgent. Multiple faults, a safety risk, and no room for error. Here’s how we kept a working dredger safe and compliant.

Jump to section

The Hanson Thames, operated by Heidelberg Materials, is a busy working dredger that relies heavily on its onboard HVAC systems to maintain safe and operational conditions. Our refrigeration engineers were brought in to carry out routine maintenance and investigate faults across a number of critical air conditioning and chilled water systems.

The challenge

From the outset, our engineers were dealing with several issues:

- A failed compressor in the main chilled water plant (Circuit 1).

- A fault with the inverter PCB (printed circuit board) in Circuit 2, leaving the system non-operational.

- Suspected refrigerant leaks in the unloading room A/C units.

- Dirty filters and low glycol levels across some systems.

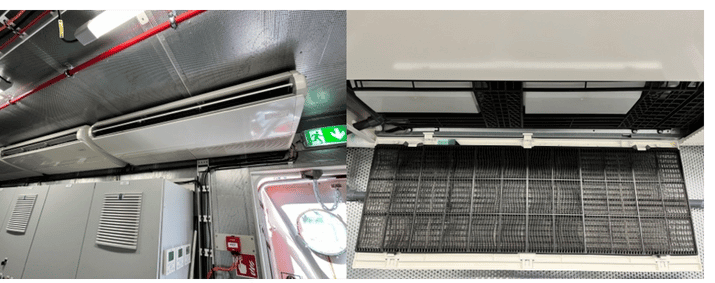

- A safety concern around the positioning of A/C units above sensitive PLC (programmable logic controller) switchboards.

To complicate matters, parts of the system had already failed or been shut down, so solutions needed to be fast, safe, and carefully coordinated with vessel operations.

Our solution

Over six days onboard, our engineers carried out a full range of inspections, servicing, and repairs:

- Compressor removal (Circuit 1): 24kg of R407C refrigerant was safely reclaimed and the compressor was isolated and removed for inspection.

- PCB workaround (Circuit 2): With no replacement on hand, the PCB from Circuit 1 was temporarily installed in Circuit 2 to bring the system back online.

- Condenser inspection: Condensers were fully drained, inspected, rodded, and reassembled with new gaskets.

- A/C servicing: Filters were cleaned, pressures tested, leak checks carried out, and full temperature and electrical readings were recorded.

- Leak detection: A/C System 1 in the unloading room was found to have a loose flare nut, which was tightened. The system was re-pressurised and monitored.

- Safety recommendation: We advised installing a drip tray under overhead A/C units to prevent water leaks onto critical switchboards. This was agreed with the vessel for future fitting.

Results

Our work ensured that all major HVAC systems aboard the Hanson Thames were operating safely and efficiently, with clear plans in place to complete the remaining work. We also identified and flagged a potentially serious risk, demonstrating our commitment to going beyond the job sheet when it comes to onboard safety.

- Circuit 2 was successfully brought back online and left running safely.

- All A/C systems were tested, cleaned, and left operational with no further faults.

- A refrigerant leak was identified and addressed before it could cause further issues.

- The vessel was left with clear follow-up actions: compressor refit, PCB replacement, and a drip tray installation.

- Full maintenance sheets and system readings were handed over to the ship’s captain.

What our customer said…

Find out more about Star’s onboard refrigeration & HVAC servicing and maintenance services.