Comprehensive fuel stewardship solutions for the marine industry

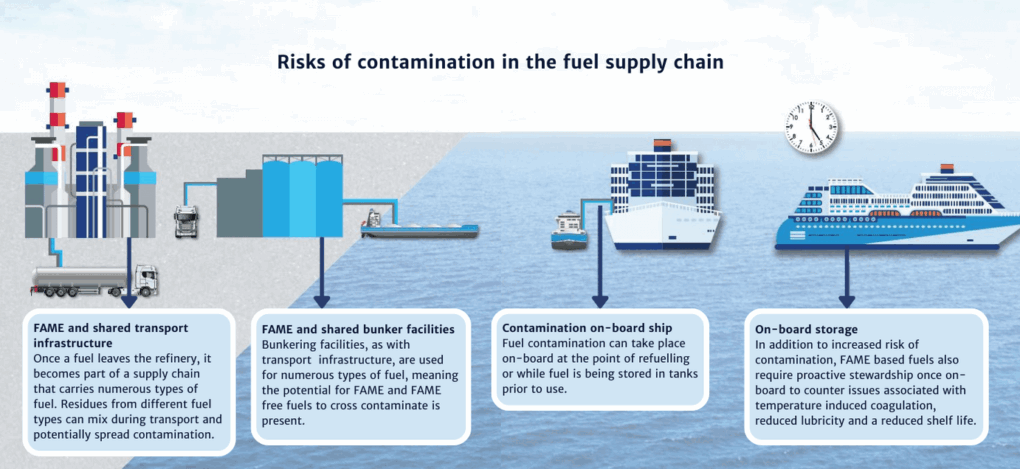

At Star, we understand the impact of fuel contamination on the efficiency and reliability of your marine operations. We’ve developed a range of solutions that addresses these challenges and covers the full cycle of fuel management.

Fuel maintenance & contamination prevention

Don’t leave your fuel quality to chance. Good fuel stewardship is essential for maintaining reliable performance and protecting your valuable assets, by preventing the buildup of harmful deposits and sludge

Your solutions…

Aquafighter fuel tank filters

Simple yet effective, these filters capture and remove free and emulsified water in directly in the fuel tank to prevent diesel bug, and protect the tank and filters. Various sizes and shapes to suit tank openings, sizes & configurations are available.

Star Mariner fuel maintenance additives

Our range of marine fuel treatment additives are designed to protect the integrity of fuel on-board ship, and are effective with Marine Gas Oils (MGOs) and low sulphur alternatives, acting to neutralise and prevent contamination, improve shelf life and counter temperature induced coagulation.

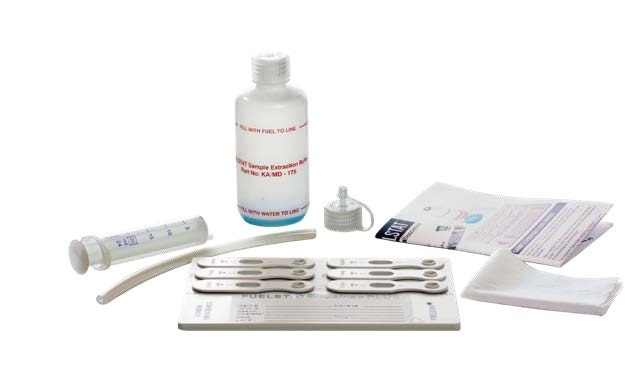

Fuel contamination testing & analysis

Onboard testing identifies any problems at the point of refuelling and at sea, meaning contamination risks can be minimised and suppliers held to account. This helps to avoid unnecessary downtime and costly long-term damage to hardware.

Your solutions…

Star FUELSTAT contamination test kit

An on-board testing solution that detects Hormoconis resinae (diesel bug), bacteria, fungi and yeast contaminants in as little as 10 minutes.

Star XRF onboard sulphur tester

Our on-board analyser confirms sulphur content in fuel within a range of 0.1% – 5.0%, allowing validation of fuel for vessels operating within and outside of designated Emission Control Areas (ECAs).

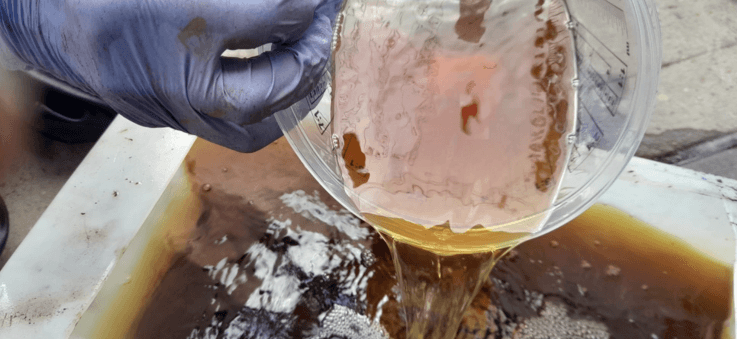

Fuel treatment

If the worst happens and your fuel becomes compromised, we can offer a range of additives to tackle it and protect against degradation.

Your solutions…

Star Mariner fuel treatment additives

Star Mariner Eliminator is a biocide that eradicates and prevents microbial contamination of fuel (diesel bug).

Fuel treatment services

We offer an all-inclusive approach to ensuring onboard fuel quality, delivered by expert technician’s on-board ship. This includes: fuel sample analysis, fuel polishing and conditioning; and fuel tank & system cleaning.

Contact us today to find out more.